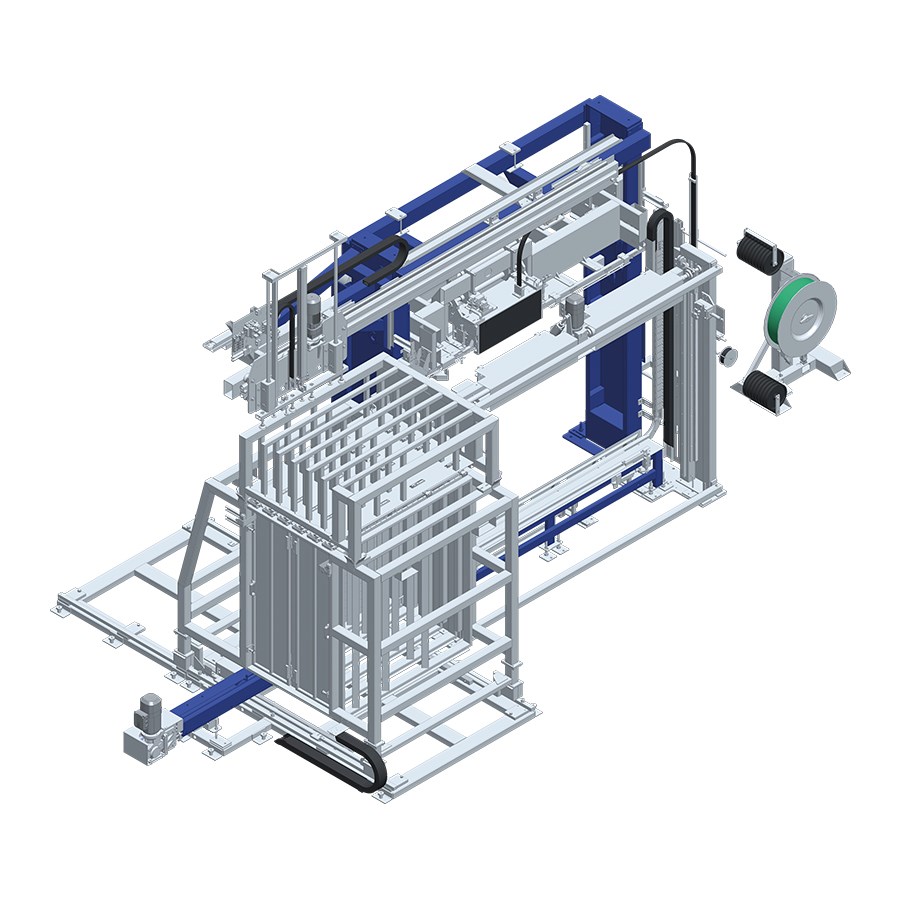

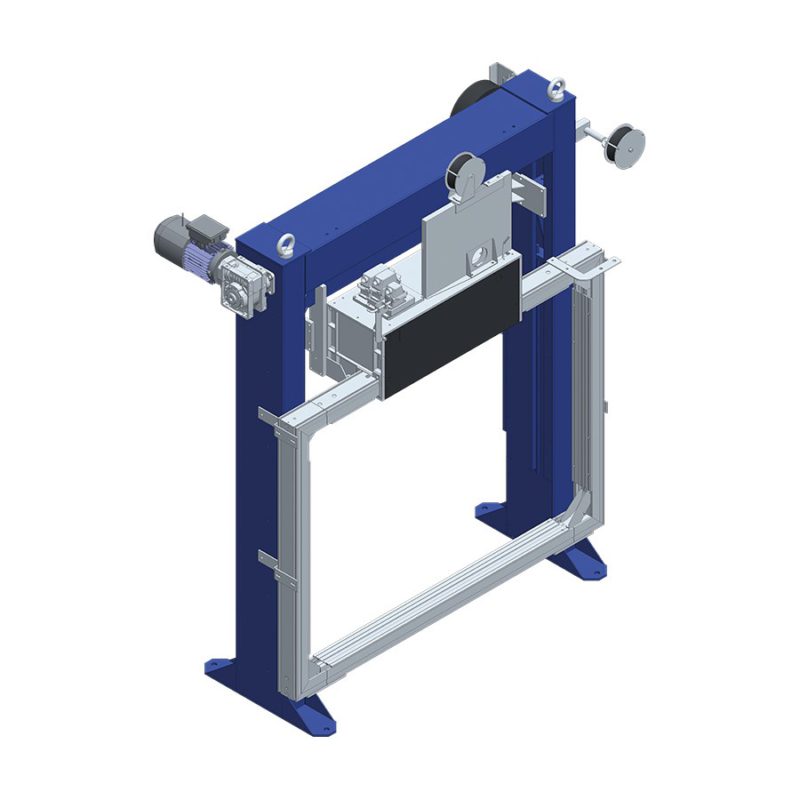

PBTS Top Seal Strapping System

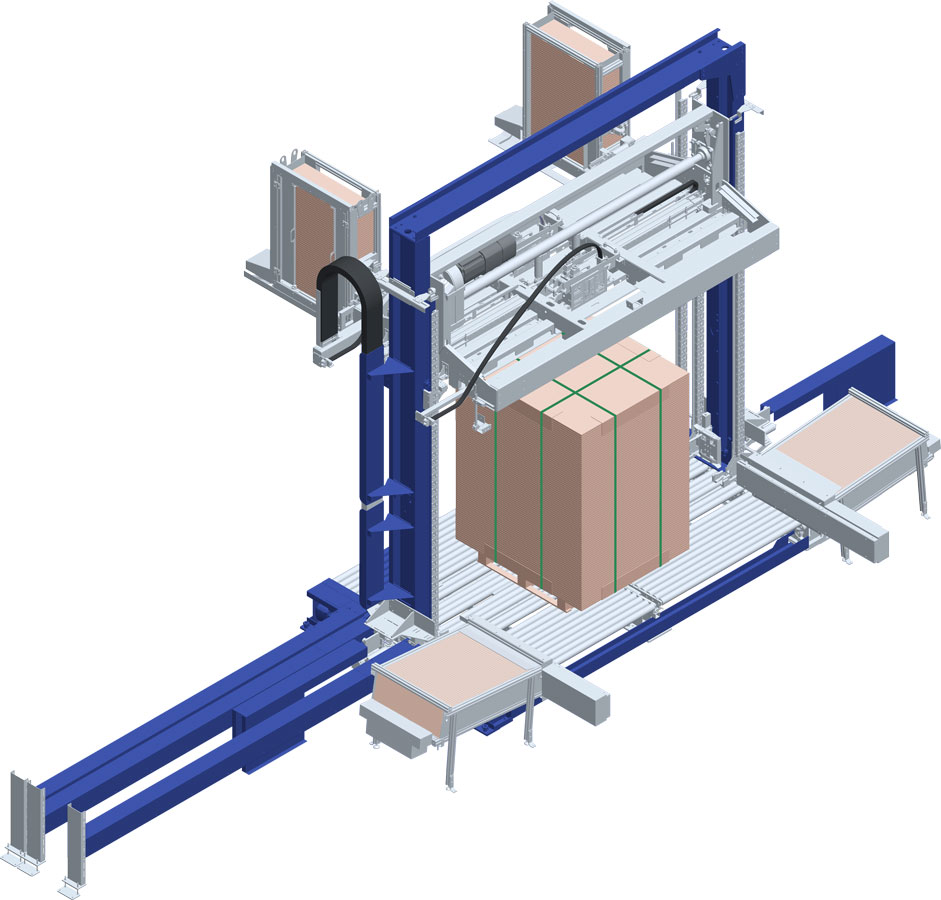

This machine is a vertical strapping machine with head that comes down from the up position. When the machine receives a signal from the conveyor (optional) of package in position, the head goes down until it touches the top side of the package by means of a mechanical switch, and it makes the strap. Then it goes back up and it waits a signal to remake the same operation. At the same time it gives another signal of end strap to the conveyor system in order that the package goes out from the line.

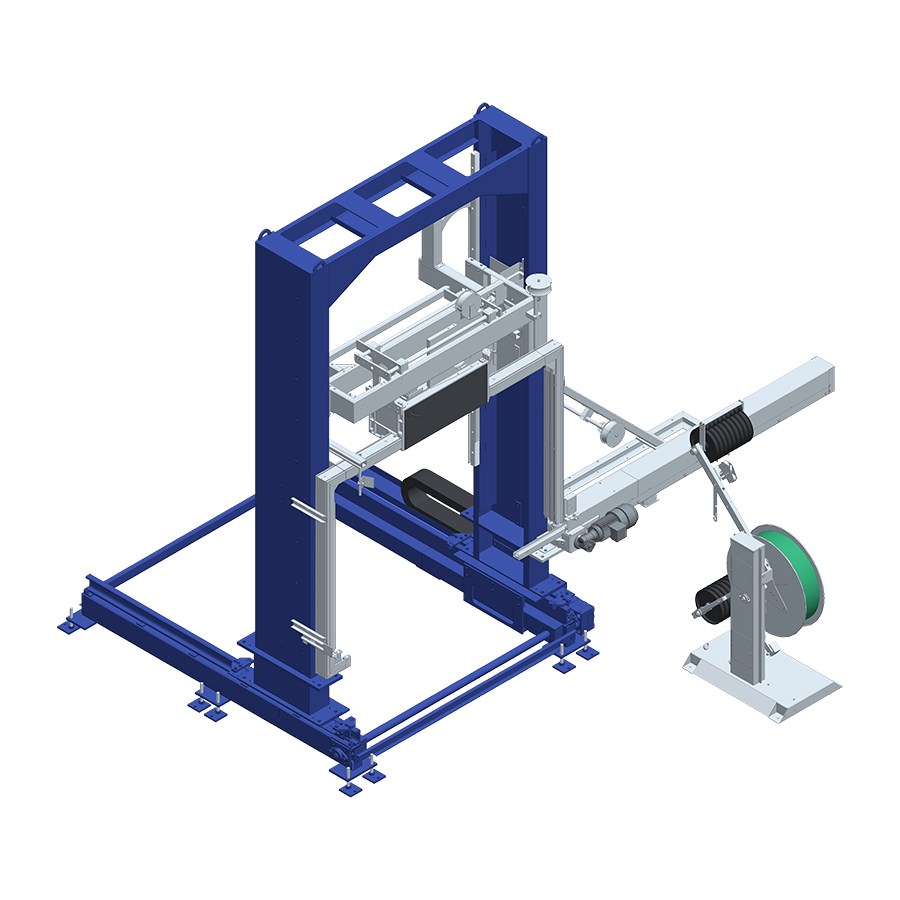

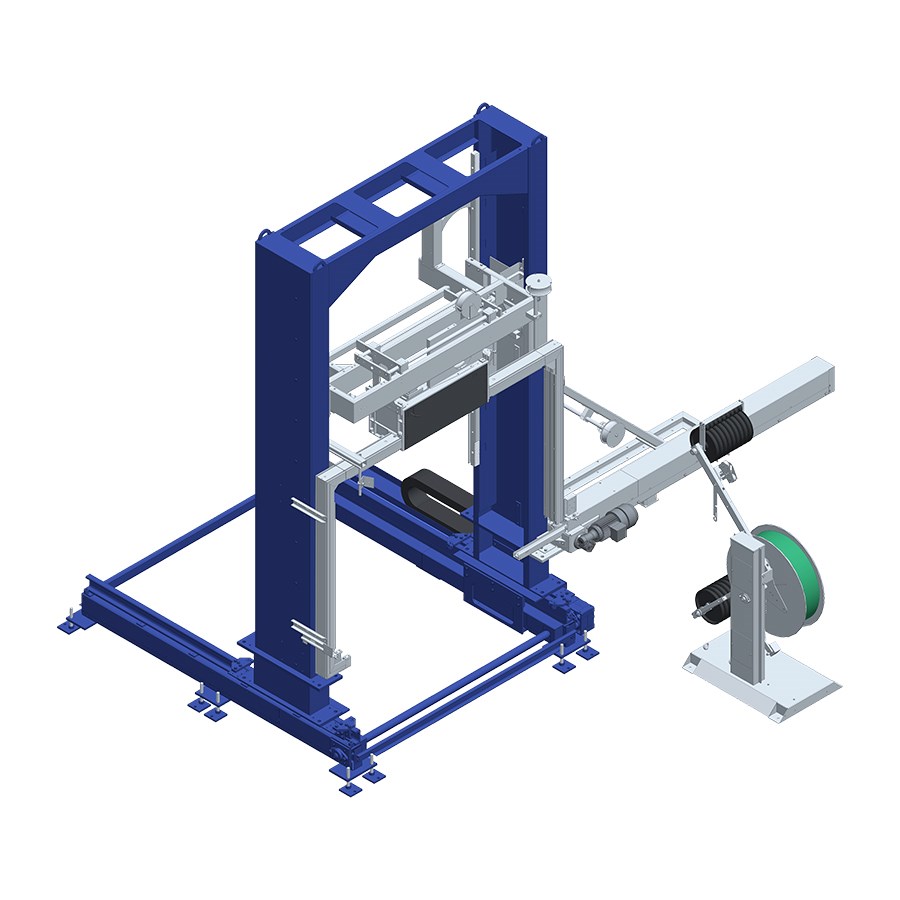

The machine is made of sturdy frame in electro-welded sheet metal profiles, support all the parts which form the strapping machine:

- TR Strapping Head (our international patent) which automatically carries out the feeding, recovery, tensioning, welding and cutting operations.

- Track for the strap to run around the pack made of a low friction material highly resistant to wear. The arches are equipped with a special releasing device with multiple independent segments to ensure perfect strap centering around the pack.

- Strap centering is further guaranteed by a system of guide brushes

- Vertical movement of the whole group carrying the strapping head and arch, with automatic self-positioning in accordance to the package height.

- Strap feeder with electromagnetic brake with motorized strap feeding group.

- In the interior part of the frame there is the electrical board for the complete automatic operation of the machine, with electronic control card and interface card.

- In the top part of the frame there is a push button with operating panel and display to visualize all the messages for use and self-diagnostics of the machine.

- Applicable Strapping Heads : TR14/TR18/TR19/TR200.

- Strap Type: polypropylene o polyesther

- Electrical Supply 400 V 50 Hz three-phase

- Strap tensioning: up to 700 kg with TR19

- Installed Power 4,5 kW (machine with feeder device)

Already a Customer?

Contact Support Services.

Our team is standing by to help you.