Plastic Strapping

Our split resistant polypropylene and polyester strapping is designed for medium, heavy duty, and extra heavy duty applications in widths ranging from 4mm to 1-1/4” and a variety of break strengths. All of our polyester strapping is made from 100% recycled polyester (rPET). Some strap can be custom printed with company and product names, promotional messages or stock numbers.

GREENBRIDGE STRAPPING PRODUCT CATEGORIES

Polypropylene

The most economical, and best suited for light to medium bundling and light unitizing/palletizing.

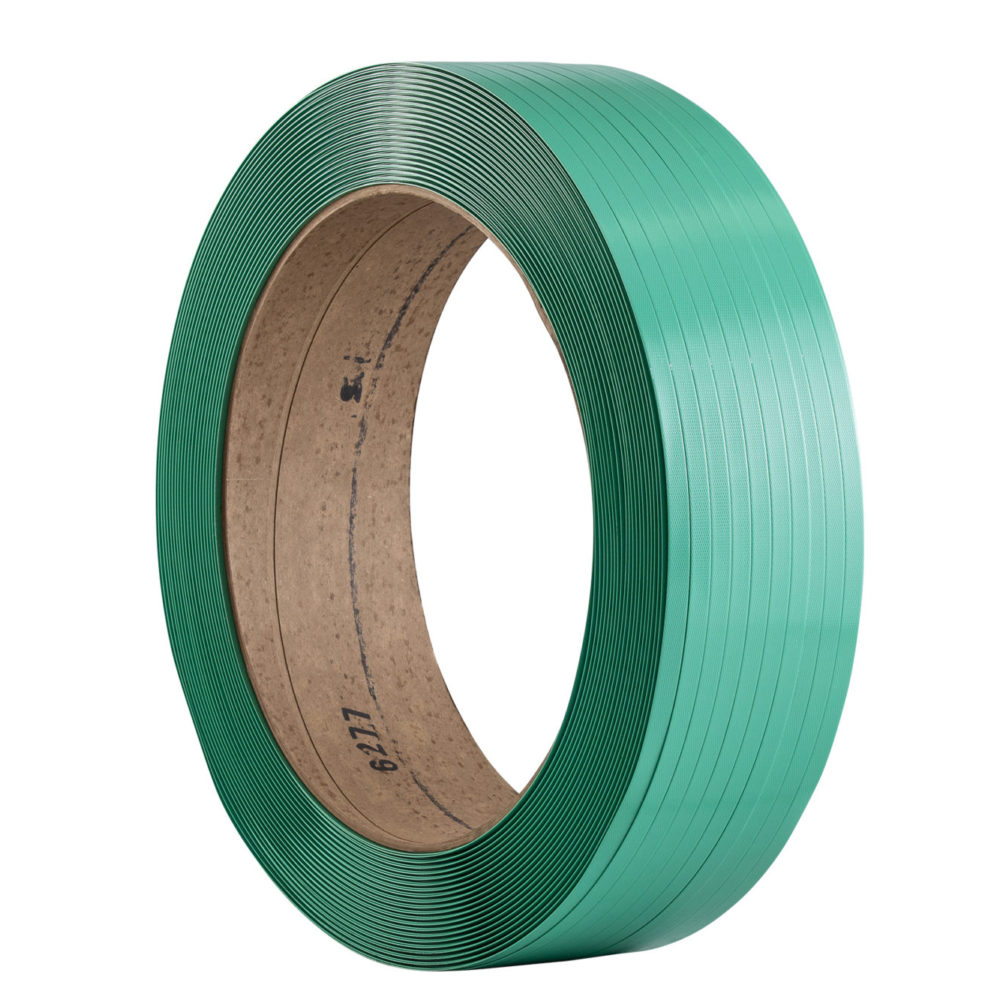

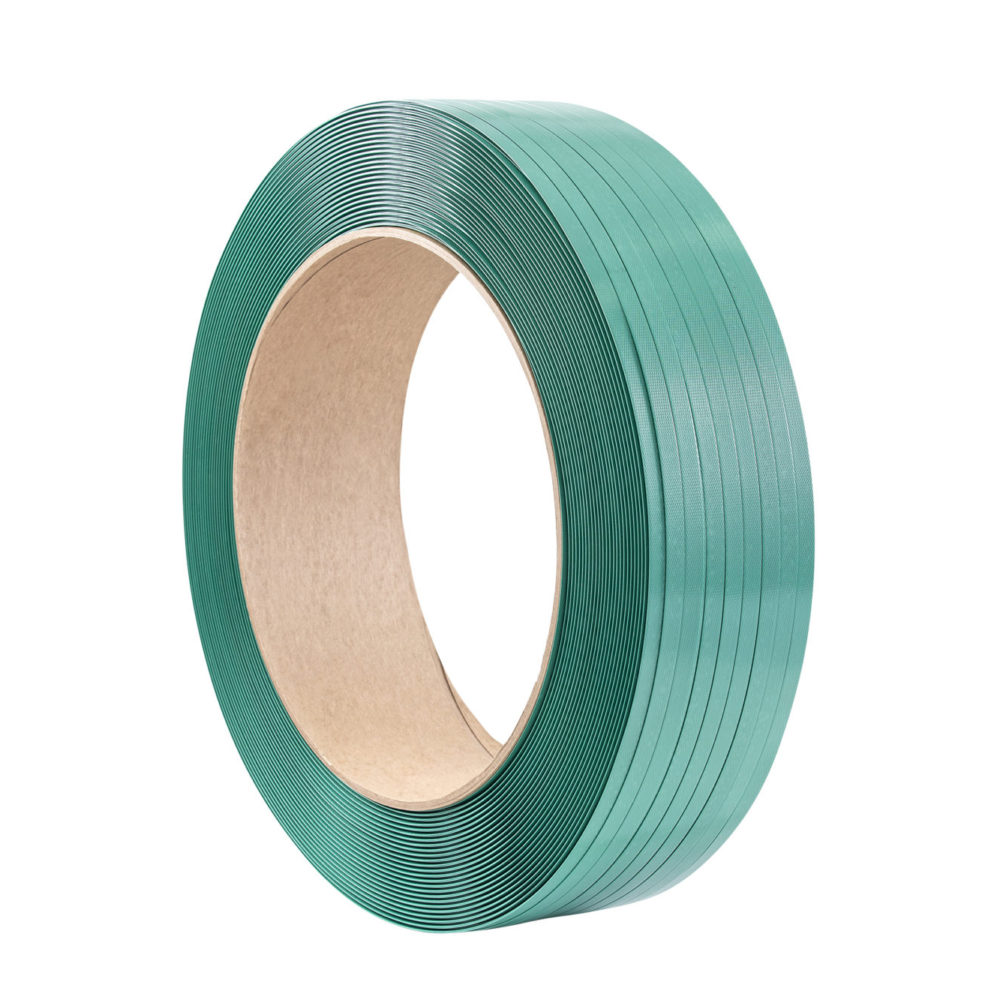

Polyester

Rapidly replacing steel for medium to heavy duty unitizing/palletizing. Except for steel, polyester has the highest retained tension of all strapping.

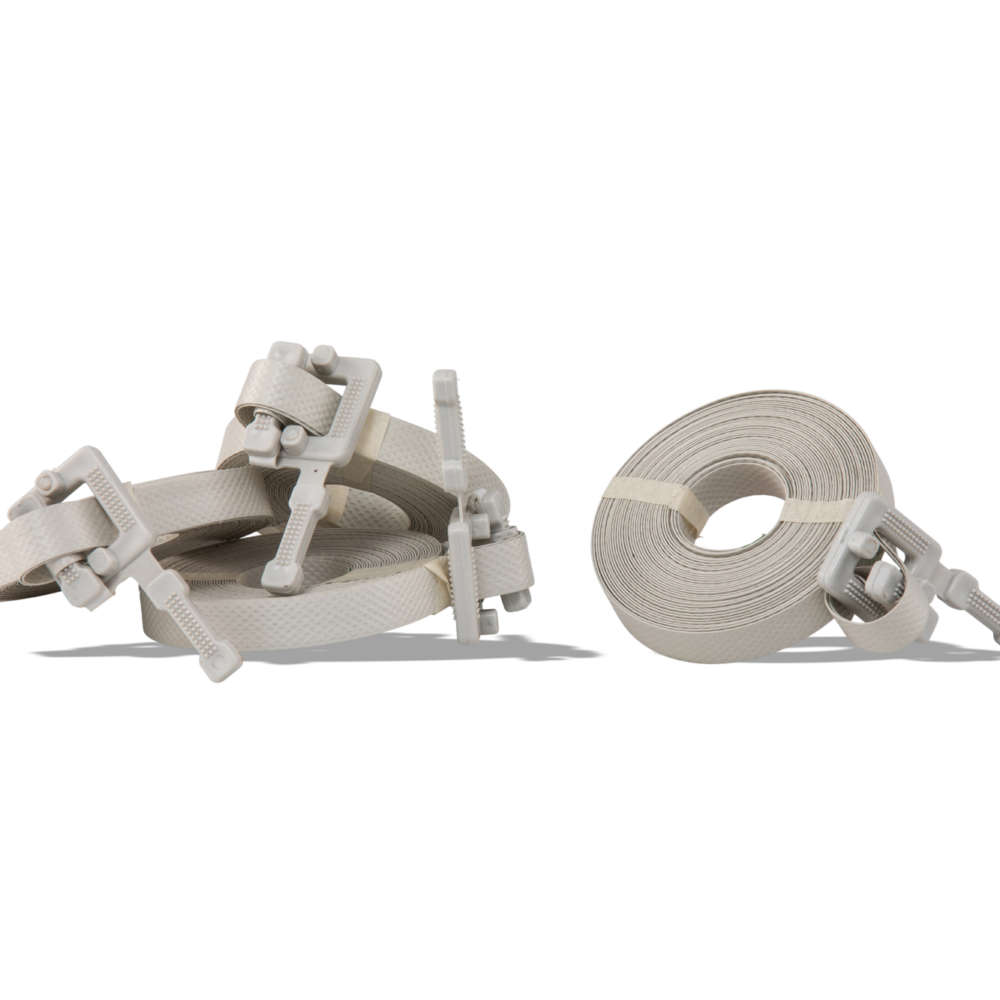

Polyester Cord Strapping

Used like a flat rope; cord is portable and requires no tools. Cord comes in five types; bonded, woven, composite, hot melt, and lashing. Woven has bi-directional fibers which provides split resistance.

Grades of Strapping

Machine/Systems Grade

Made to the highest specifications and contains no splices. It is made for use in high-speed automatic strapping machines.

Hand/Tool Grade

Made to less demanding specifications for hand applications including manual and power hand tools. Hand grade strapping may have up to one splice per coil.PET and PP strapping may be smooth or embossed and come in sheet and strand style products:

Smooth + Waxed

- Smooth strapping is generally run through friction seal equipment.

- Many smooth straps are waxed to work properly in a friction seal machine.

Embossed

- Embossed strapping is generally associated with heat seal equipment, however today there are exceptions as newer heat seal equipment will handle both smooth and embossed.

- Embossing allows for a more rapid melt for welding, split resistance, and in some strapping equipment, better feeding.

- Embossing gives the strap more rigidity (for the weight) for better feeding.

Polyester (PET)

PET can be smooth or embossed. It is only made in green or black. PET is glossy in appearance and very difficult to split.

Greenbridge’s high tensile strength polyester strapping offers a superior product at a lower cost per foot than steel strapping. In most applications, heat or friction sealing the strap eliminates the extra cost and inventory of

metal seals. More efficient, the typical PET coil weighs about half as much as a coil of steel and has more than twice the footage, reducing time consuming coil changeovers. For improved impact resistance, stain resistance, weather resistance, elongation, recovery, disposability and safety, polyester has no equal. When you combine all the above advantages with the fact that your customers are demanding it, the choice is clearly PET strapping.

Polyester (PET) Advantages

- High strength/tension

- Low elongation

- Large packages

- Economics/high volume

- Recyclability/sustainability

Polypropylene (PP)

Polypropylene is usually, but not always, textured or embossed. Polypropylene is most commonly made in black, white, yellow, and clear. Polypropylene is an economical solution.

Polypropylene (PP) Advantages

- Light duty bundling and arch machines (ex: newspapers)

- PP made in 3/16” PET in 3/8” min.

- Easy to open seals

- Better colors, printing & branding

- Lighter weight (30 lb/coil vs. 50 lbs/coil)

Showing all 7 results

Already a Customer?

Contact Support Services.

Our team is standing by to help you.